In recent years, with the rapid development of science and technology, automated welding technology has gradually become the mainstream of industrial production. However, manual welding, as a traditional welding process, still plays an irreplaceable role in many fields. Recently, at a welding technology exhibition, the unique charm of manual welding attracted the attention of many visitors, showing the rebirth of this traditional process in modern manufacturing.

Manual welding is a process that relies on the welder’s skills and experience to manually operate welding equipment to connect metals. Although automated welding technology has obvious advantages in efficiency and precision, manual welding still shows its unique flexibility and adaptability in complex structures, special materials and small batch production. Especially in the fields of aerospace, automobile manufacturing and art production, the fine craftsmanship and personalized service of manual welding have become the first choice of many companies and craftsmen.

At the exhibition, welding experts and craftsmen from different fields shared their manual welding experiences. A well-known welding craftsman said: “Manual welding is not only a technology, but also an art. Every welding is a dialogue with the material, and every action of the welder contains the understanding of the process and the pursuit of quality.” This love and persistence for manual welding is the driving force behind the continuous development of this traditional craft.

In addition, manual welding also shows its advantages in environmental protection and sustainable development. With the increasing global environmental protection requirements, many companies have begun to pay attention to resource utilization and waste reduction in the production process. Due to its flexibility, manual welding can be adjusted according to actual needs, reducing material waste and reducing production costs. At the same time, the repair ability of manual welding has also enabled many old equipment to be revitalized and extended its service life.

However, the inheritance of manual welding faces challenges. As the younger generation pursues high-tech careers, fewer and fewer people are willing to join the manual welding industry. To this end, many weldin associations and vocational schools have begun to actively promote manual welding training courses to attract more young people to join this industry. By holding competitions, exhibitions, lectures and other activities, the social awareness of manual welding is improved and the interest of young people is stimulated.

In general, manual welding, as a traditional craft, still has new vitality in modern manufacturing. It not only carries rich culture and history, but also shows unique value in today’s society. With the attention and promotion of manual welding, this craft will surely play an important role in more fields in the future.

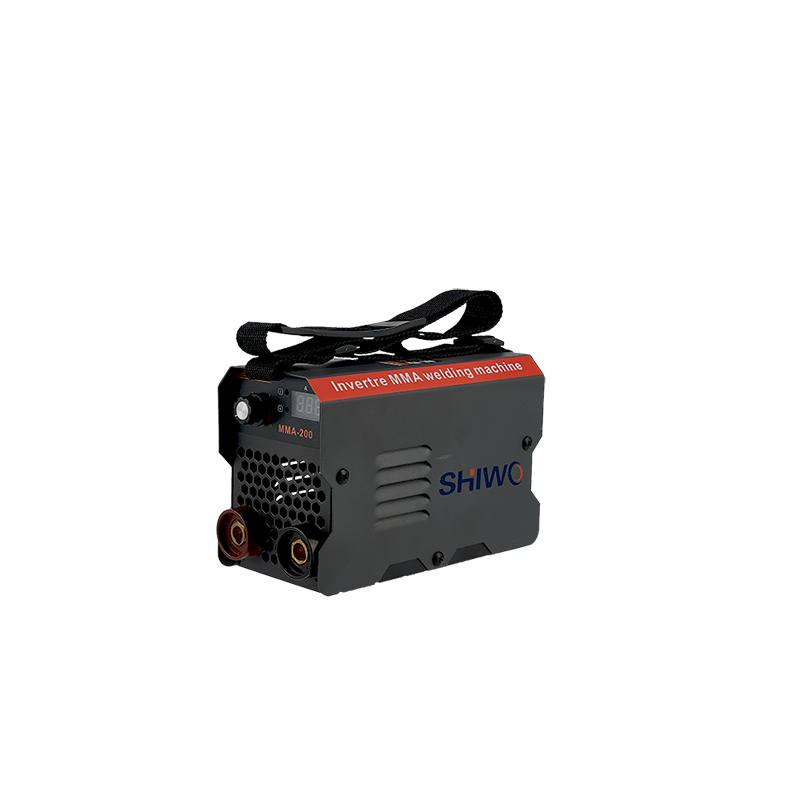

About us, Taizhou Shiwo Electric & Machinery Co,. Ltd is a big enterprise with industry and trade integration, which is specializing in manufacturing and exporting of various kinds of welding machines, air compressor, high pressure washers, foam machines, cleaning machines and the spare parts. The headquarter is located at Taizhou city, Zhejiang province, South of China. With modern factories covering an area of 10,000 square meters, with more than 200 experienced workers. Besides, we have more than 15 years of experience in supplying chain management of OEM & ODM products. Rich experience helps us to constantly develop new products to meet the ever-changing market needs and customer requirement. All of our products are greatly appreciated in Southeast Asia, European, and South American markets.

Post time: Dec-13-2024