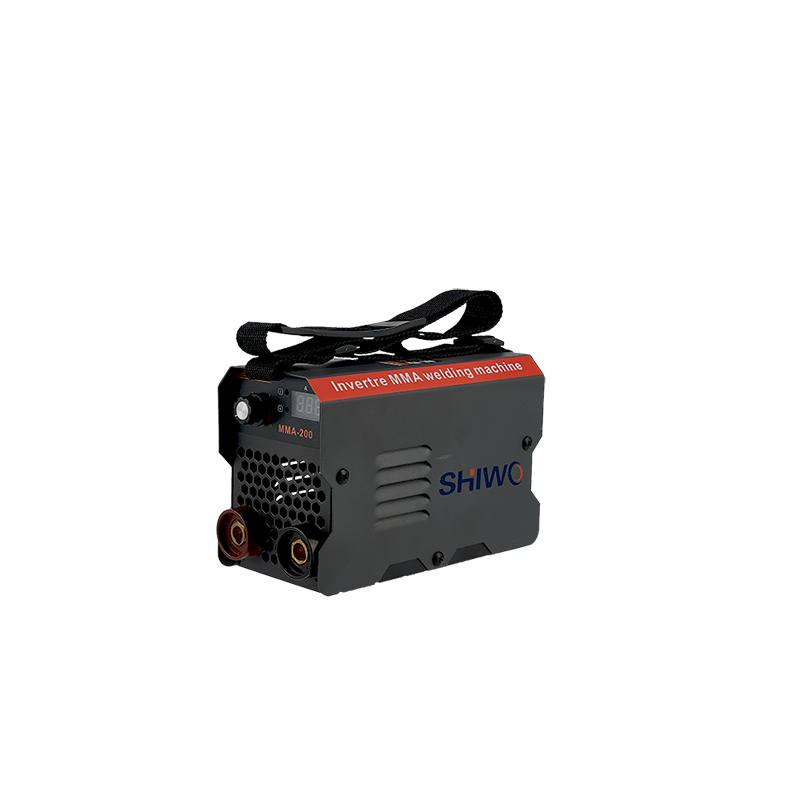

In today’s industrial and manual manufacturing fields, electric welding machines, as key tools, are undergoing significant changes. Among them, mini welding machines and large-capacity welding machines have become two categories that have received great attention in the market.

Mini welders have quickly found their place in personal and small repair scenarios because of their compact design and lightweight features. They are easy to carry and relatively easy to operate, allowing ordinary consumers to do some simple metal processing and repair work at home. For example, a citizen who likes to make things by himself said: “With the mini welding machine, I can make some small metal decorations by myself, which is very convenient.”

Large-capacity welding machines rely on their powerful power and efficient performance to become the first choice for large-scale industrial manufacturing and construction projects. In fields such as welding of large steel structures, shipbuilding, and heavy machinery processing, large-capacity electric welding machines can continuously and stably output large currents to ensure the quality and efficiency of welding. An engineer from a large manufacturing company said: “For large-scale production companies like ours, large-capacity welding machines are key equipment to improve production efficiency and ensure product quality.”

As technology continues to advance, mini welding machines continue to improve in performance and are gradually able to meet some more complex welding needs. At the same time, large-capacity welding machines are also developing in the direction of intelligence and energy saving to meet the requirements of environmental protection and efficient production.

Market research shows that the market demand for mini welding machines and large-capacity welding machines continues to increase. This not only reflects consumers’ various needs for personalized manufacturing and industrial production, but also prompts welding machine manufacturers to continuously innovate and optimize products.

In the future, we have reason to believe that mini welding machines and large-capacity welding machines will continue to play an important role in their respective fields, providing strong support for promoting the development of manufacturing and the realization of personal creativity.

About us, Taizhou Shiwo Electric & Machinery Co,. Ltd is a big enterprise with industry and trade integration, which is specializing in manufacturing and exporting of various kinds of welding machines, air compressor, high pressure washers, foam machines, cleaning machines and the spare parts. The headquarter is located at Taizhou city, Zhejiang province, South of China. With modern factories covering an area of 10,000 square meters, with more than 200 experienced workers. Besides, we have more than 15 years of experience in supplying chain management of OEM & ODM products. Rich experience helps us to constantly develop new products to meet the ever-changing market needs and customer requirement. All of our products are greatly appreciated in Southeast Asia, European, and South American markets.

Post time: Oct-25-2024