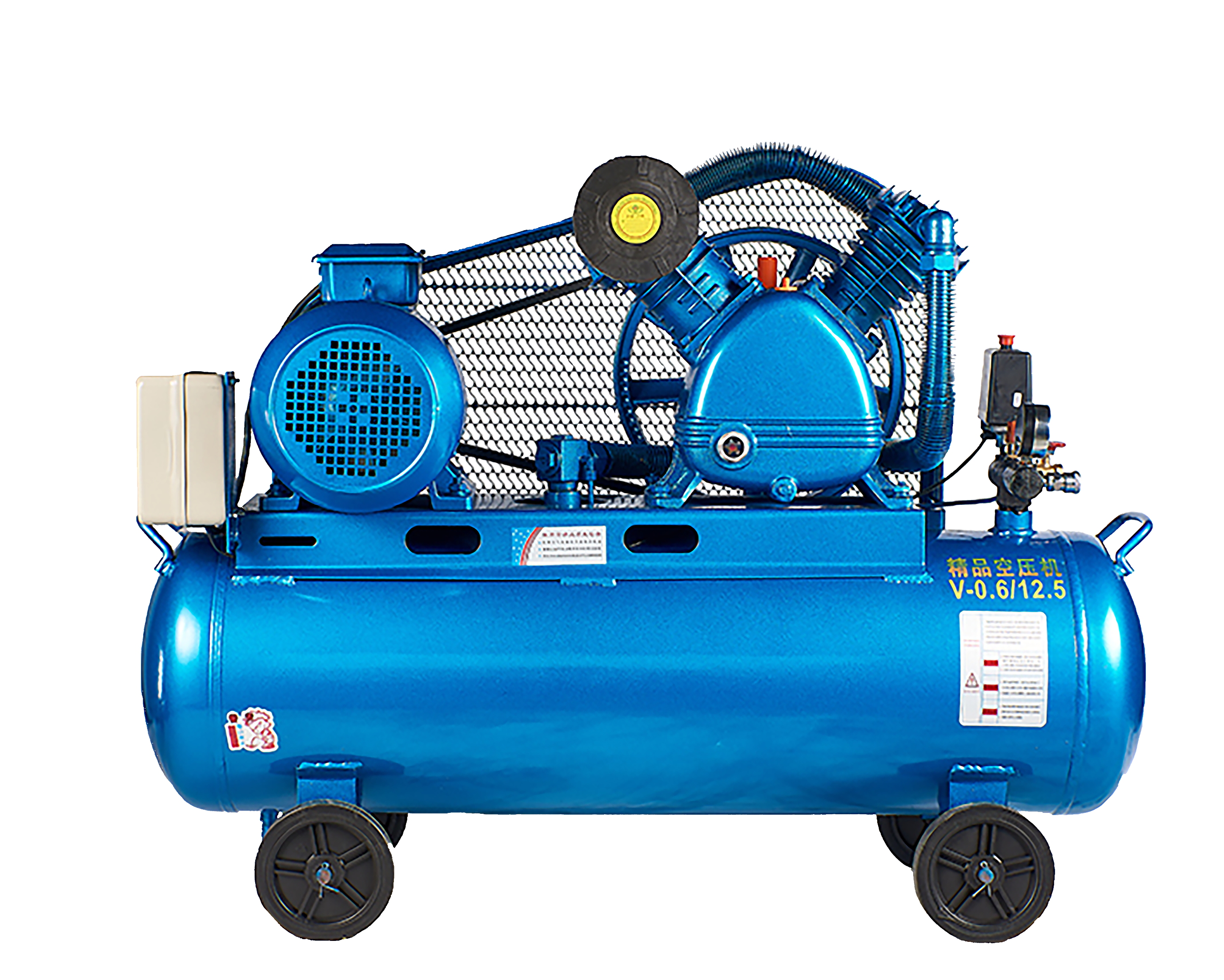

An air compressor is a device used to compress gas. Air compressors are constructed similarly to water pumps. Most air compressors are reciprocating piston, rotating vane or rotating screw. Today we will talk about the difference between belt air compressor and oil-free air compressor.

Belt air compressors and oil-free air compressors are two different types of air compressors. They have some differences in principles, uses and methods of use.

principle:

The working principle of the belt air compressor mainly relies on the reciprocating motion of the piston to achieve gas compression. When the piston moves from the top dead center of the cylinder to the bottom dead center, the volume in the cylinder increases and the pressure in the cylinder decreases. When the pressure inside the cylinder is lower than the outside atmospheric pressure, outside air enters the cylinder due to the pressure difference between the inside and outside of the cylinder. When the piston moves to bottom dead center, the cylinder is filled with air and its pressure is equal to the outside atmosphere. Subsequently, when the piston moves from the bottom dead center to the top dead center, because the inlet and outlet valves are closed, the air in the cylinder is compressed. As the piston moves upward, the volume of the cylinder continues to become smaller, and the pressure of the compressed air increases. The higher it is, the compression process is completed1.

The oil-free air compressor mainly achieves gas compression by driving the piston through a motor to reciprocate, without adding lubricant throughout the process. The core of the oil-free air compressor is the outstanding two-stage compression host. The rotor has been refined through twenty processes to achieve unparalleled precision and durability in the rotor line shape. High-quality bearings and precision gears are installed inside to ensure the coaxiality of the rotor and make the rotor fit accurately to maintain long-term, efficient and reliable operation. The sealing link of the oil-free air compressor uses oil-free seals made of stainless steel and a durable labyrinth design. This set of seals can not only prevent impurities in the lubricating oil from entering the rotor, but also prevent air leakage and ensure a steady flow of air. Continuously produce clean, oil-free compressed air

use:

Belt air compressor: commonly used in general industrial production, such as automobile manufacturing, mechanical processing and other fields.

Oil-free air compressor: suitable for occasions with high air quality requirements, such as medical equipment, food processing and other fields.

About us, Taizhou Shiwo Electric & Machinery Co,. Ltd is a big enterprise with industry and trade integration, which is specializing in manufacturing and exporting of various kinds of welding machines, air compressor, high pressure washers, foam machines, cleaning machines and the spare parts. The headquarter is located at Taizhou city, Zhejiang province, South of China. With modern factories covering an area of 10,000 square meters, with more than 200 experienced workers. Besides, we have more than 15 years of experience in supplying chain management of OEM & ODM products. Rich experience helps us to constantly develop new products to meet the ever-changing market needs and customer requirement. All of our products are greatly appreciated in Southeast Asia, European, and South American markets.

Post time: Sep-02-2024